The usual cam functions (also known as valve events) are Intake Opening Point, Intake Closing Point, Exhaust Opening Point, Exhaust Closing Point, Overlap, Lobe Separation Angle, and Valve Lift. Longer duration cams generally need more staticĬompression. More tolerant of extended (late intake closure) cam timing. More mixture at the same point of intake valve closure. Piston movement upwards away from BDC on the compression stroke, and will capture Short-rod motors (“n” = 1.4 to 1.75:1) will have the piston closer to BDC than the long-rod motor at any point between 90° BBDC & 90° ABDC. Long-rod motors (“n” = 1.75 to 2.1:1) will have the piston closer to TDC than the short-rod motor at any point between 90° BTDC & 90° ATDC. A safe limit for “Z” is about 100,000 f/s 2, although this will cause ring flutter with 1/16” compression rings. Where “Z” is piston acceleration in feet per second, per second, “N” is engine RPM, “S” is the stroke length in inches, “n” is the rod-to-stroke ratio (as described, supra ), and 2189 is a constant. A better method of calculating maximum RPM is based on the point of fastest piston acceleration, and takes into account the rod length (longer rods improve the safe RPM slightly). Since this speed is not constant throughout the engine’s rotation, piston speed is only an average. About 4,000 f/m is safe for good-quality cast pistons and up to 5,000 f/m for forgings, for peak power only - shifting, not cruising!

Where “P” is piston speed in feet per minute, “S” is the stroke in inches, “R” is engine RPM, and 6 is a constant. The only 2 exceptions are 0° (TDC) where both strokes are zero, and 180° (BDC) where both strokes are equal & nominal.īy the way, the usual limit of engine speed based on the stress of the reciprocating components is not RPM, it’s piston speed. Two motors with the same stroke, but different rod lengths, will not have the piston in the same place at the same point of crankshaft rotation. The piston’s motion during crankshaft rotation is not symmetrical: the piston speed before & after TDC is faster than before & after BDC, but the difference is not constant - it varies with the rod ratio. Of intake valve closure partially depends on the motor’s rod ratio. The percentage of mixture captured, compressed, and burned in the cylinder at a specific point Except for purpose-built racing engines, most other projects are compromises where 1.75 may not produce the best results.

99% of all motors fall between these 2 extreme limits, with most standard production designs between 2.0:1 and 1.45:1.Īn “n” value of 1.75 is considered “ideal” by some respected engine builders, if the breathing is optimized for the design. The ratio of rod length to stroke length (usually represented by the symbol “n” ) is almost always between 2.1:1 on the “long” end, and 1.4:1 on the “short” end.

The geometric relationship between the rod and the rod journal is one not generally understood, but which plays a key role in the motor’s breathing and overall power characteristics. The crankshaft’s connecting rod journal (or “throw” ) is offset from the main journal by exactly ½ the stroke length. This last factor is not fully appreciated by most mechanics. Intake valve closing point (generally the 2 nd number in the cam timing data, given in degrees after bottom dead center, or ABDC) Theoretical or mechanical compression ratio (advertised, static, or nominal), including corrections made for changes in the combustion chamber volume due to variations in piston compression distance, changes in piston dome shape such as valve reliefs and flame slots, chamber modifications such as larger valve installations, combustion chamber re-shaping, bore notches for valve relief, alternate gasket thickness, head and/or block milling, &c.

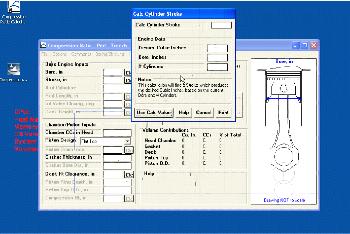

#Camshaft compression calculator how to#

This article discusses briefly how to roughly calculate how changes in eitherĬam timing, compression, or both affect low-speed torque and response. The experienced engine builder (Mopar, Harley-Davidson, or Ferrari) knows that the “advertised” compression ratio (suggested by the owner’s manual, piston manufacturer, &c.) is only one of several factors involved in determining how much pressure is developed in the combustion chamber.

0 kommentar(er)

0 kommentar(er)